Ms. kawan Lai

Leave a message

Ms. kawan Lai

Leave a messagepp board, also known as polypropylene (PP) board (PP pure board, modified PP board, reinforced PP board, PP electrode), is a semi-crystalline material. It is harder and has a higher melting point than PE. Since the homopolymer type PP temperature is very brittle above 0 °C, many commercial PP materials are random copolymers with 1-4% ethylene or higher ratio ethylene content clamp copolymers.

Introduce:

Product Name: PP Copolymer type material has low heat distortion temperature (100 ° C), low transparency, low gloss, low rigidity, but has stronger impact strength. PP strength increases as the ethylene content increases. The Vicat softening temperature of PP is 150 °C. Due to the high degree of crystallinity, this material has excellent surface stiffness and scratch resistance. There is no environmental stress cracking problem in PP. Typically, PP is modified by the addition of glass fibers, metal additives or thermoplastic rubber. The flow rate of PP has a MFR ranging from 1 to 40. Low MFR PP materials have better impact resistance but lower elongation. For materials of the same MFR, the strength of the copolymer type is higher than that of the homopolymer type. Due to crystallization, the shrinkage rate of PP is quite high, generally 1.8 to 2.5%. And the direction uniformity of shrinkage is much better than materials such as PE-HD. The addition of 30% glass additive can reduce the shrinkage to 0.7%. Both the homopolymer type and the copolymer type PP materials have excellent moisture absorption resistance, acid and alkali corrosion resistance, and solubility resistance. However, it is not resistant to aromatic hydrocarbons such as benzene solvents, chlorinated hydrocarbons (carbon tetrachloride) solvents, and the like. PP does not have oxidation resistance at high temperatures like PE.

Classification:

1.Pure PP board: Low density, easy to weld and process, excellent chemical resistance, heat resistance and impact resistance, non-toxic, odorless, currently the most environmentally friendly project

2.Polypropylene (PP) extruded sheet: It is a Plastic Sheet made by adding PP resin into various functional additives through extrusion, calendering, cooling, cutting and other processes.

3.Glass fiber reinforced PP board: Glass fiber reinforced PP board (FRPP board): After being reinforced by glass fiber by 20%, in addition to maintaining the original excellent performance, the strength and rigidity are doubled compared with PP, and it has good heat resistance and low temperature impact. , anti-corrosion and arc resistance, low shrinkage. Especially suitable for chemical fiber, chlor-alkali, petroleum, dyes, pesticides, food, medicine, light industry, metallurgy, sewage treatment and other fields.

4.PPH board, beta (β)-PPH single-sided non-woven sheet. (β)-PPH products have excellent heat-resistant oxygen aging properties, long service life and good mechanical properties. It has been successfully used in the production of sheet metal, and advanced technology is in a leading position in China. These products can be used in filter plates and spiral wound containers, for FRP wound liners, petrochemical industry storage and transportation, transportation and anti-corrosion systems, power plants, water plants, water supply, water treatment and drainage systems; and steel plants, power plants Dust removal, washing and ventilation systems, etc.

Application:

PP extruded sheet has the characteristics of light weight, uniform thickness, smooth surface, good heat resistance, high mechanical strength, excellent chemical stability, electrical insulation and non-toxicity. PP board is widely used in chemical containers, machinery, electronics, electrical appliances, food packaging, medicine, decoration and water treatment. The practical temperature of the PP plate can reach 100 degrees.

1.Acid and alkali resistant equipment, electroplating equipment, solar photovoltaic equipment, environmental protection equipment, waste water, exhaust gas discharge equipment, washing towers, clean rooms, semiconductor plants and related industrial equipment, is also the preferred material for the manufacture of plastic water tanks, of which PP thick plates Widely used in stamping plates, punching mattress boards, etc.

2. Recycling bins, including recycling bins, fruit and vegetable crates, storage bins, and stationery boxes in various industries;

3. Industrial boards, including wire and cable over-packaging protection, glass, steel plates, packaging protection for various items, mats, shelves, partitions, bottom plates, etc.;

4. Protection board, the era of building materials in the construction of cardboard and plywood is gone forever. With the advancement of the times and the improvement of taste, to ensure the integrity of the decoration design before the completion of the construction, appropriate protection should be given to maintain the operation. Economical, safe and convenient, as well as protection of the building's elevators and floors before acceptance.

5. Electronic industry protection. Conductive packaging products are mainly used in the packaging of electronic components such as IC wafers, IC packages, tests, TFT-LCDs, optoelectronics, etc., in order to avoid contact with other charged objects, causing spark damage caused by charge friction. There are also conductive, antistatic plastic panels, totes and so on. PP board can be used in addition to the above products, but also on the back of the washing machine, refrigerator insulation layer, frozen food, medicine, sugar and other packaging. The hollow board production line can also be used to produce PE hollow boards to supply the insulation room partitions required for urban construction and rural areas.

Size:

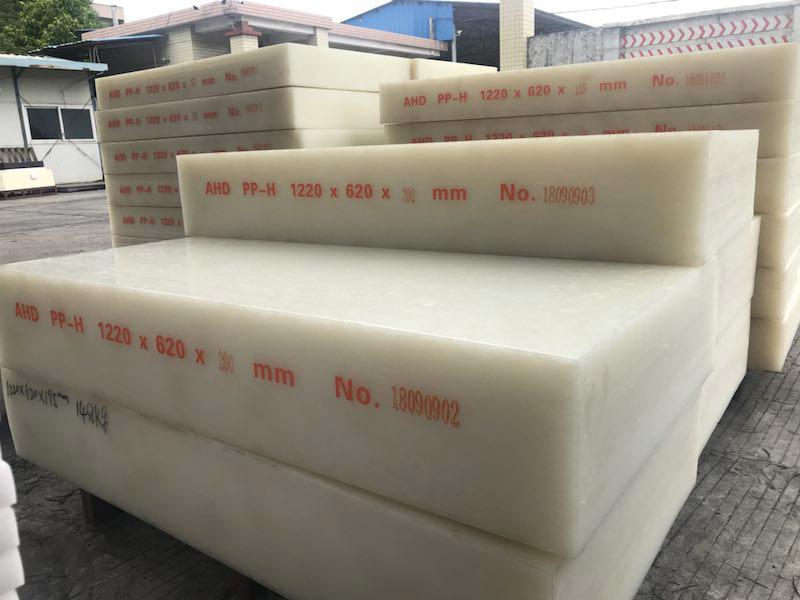

The standard size of PP Sheet made by AHD plastic:

PP-H sheet, size: 1000×2000mm, 1220×2440mm, 1500×3000mm , 610×1220 T: 1----200mm

PP-(C+H) sheet, size: 1000×2000mm, 1220×2440mm, 1500×3000mm T: 1----100mm

PP+GF sheet,size: 1000×2000mm, 1220×2440mm, 1500×3000mm T: 1----100mm

Note: The length and width can be customized according to customer requirements, the board surface is smooth and flat.

Factory direct sell, Contact us for inquiry

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.